《Chem. Soc. Rev.》: Progress and perspective for conversion of plastic wastes into valuable chemicals

Kai Zheng,+ Yang Wu,+ Zexun Hu, Shumin Wang, Xingchen Jiao,* Juncheng Zhu, Yongfu Sun* and Yi Xie*

Plastic has been widely used in various industries due to its low cost, light weight, durability, processability, and enormous chemical diversity. So far, various polymers including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and polystyrene (PS) have been used to manufacture commercial plastics. Due to the huge demand for plastics in daily life, their global production has been continuously increasing exponentially in the past few decades. In the 1960s, only 15 million tons of plastic were consumed, while in 2014, approximately 311 million tons of plastic were produced, and it is expected that over 500 million tons of plastic will be needed by 2050. However, with the rapid growth of plastic production, a large amount of solid waste is also generated every year. It is predicted that from 2016 to 2030, the global amount of plastic waste will increase from 260 metric tons per year to 460 metric tons. Even worse, only about 9% of these plastic waste is recycled, of which 12% is incinerated and 79% is discarded in landfills, oceans, or nature. Due to the super stability of these plastic waste, they are difficult to degrade naturally. Therefore, it is estimated that by 2050, the world will accumulate approximately 12000 metric tons of plastic waste. These discarded plastic waste will cause huge damage to our lives, as they can cause water pollution, farmland damage, and even more surprising, a new research report states that multiple types of microplastics have been detected in human feces. Given these reasons, people urgently need to seek more strategies to recycle these waste plastics.

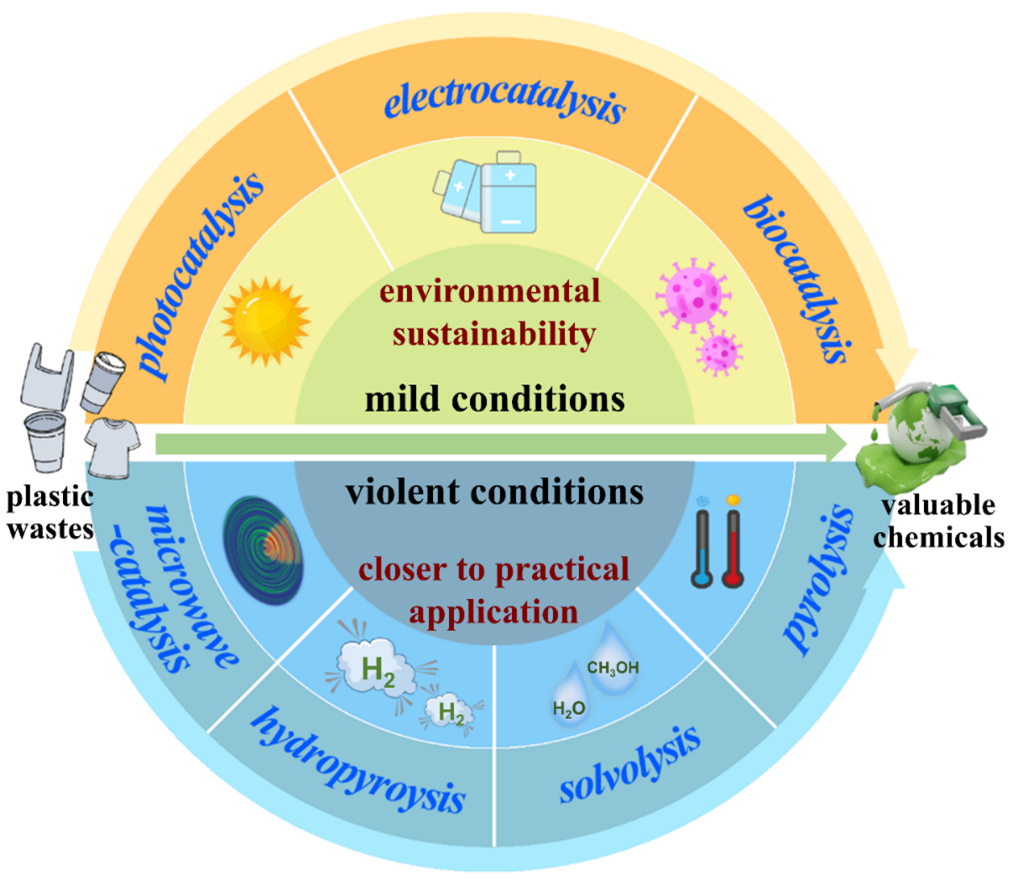

So far, various strategies for plastic conversion have been developed, each with its own advantages and disadvantages. Recently, there have been many reviews on the degradation or recycling of waste plastics, most of which only list strategies for converting them into chemicals. However, few people pay attention to the internal conversion mechanisms of various methods. In view of this, in this review, we categorize the latest plastic conversion strategies into two categories, namely those conducted under severe and mild conditions (Figure 1), and promptly summarize their corresponding internal mechanisms. We have summarized the strategies under severe conditions such as high temperature and pressure, which are closer to practical applications due to their excellent conversion efficiency; At the same time, the strategy of isothermal and under normal temperature and pressure conditions has enormous development potential in the future due to its environmental friendliness. Specifically, we reviewed the pyrolysis of plastics at high temperatures through a continuous two-step process; This article reviews the application of bifunctional metal/acid catalysts in the hydropyrolysis of plastics; This article reviews the catalytic conversion of plastics through solvent assisted tandem catalytic cross alkane metathesis at relatively low temperatures; This article reviews the one-step microwave catalyzed conversion of plastics to produce high value-added chemicals. Subsequently, we outlined the two-step method of simulating natural environmental conditions and elaborated on the photocatalytic effect of plastics in detail; An overview was given of the three step electrocatalytic conversion of plastics under ambient temperature and pressure; This article reviews the biocatalytic effects of bifunctional enzyme systems on plastics at atmospheric pressure and room temperature. Finally, we look forward to improving existing plastic recycling technologies through in situ characterization techniques and theoretical analysis. We hope that this review can deepen readers' understanding of the most advanced plastic recycling technologies and understand the latest developments in plastic recycling.

The first authors of this article are Dr. Kai Zheng and Dr. Yang Wu from the University of Science and Technology of China. The corresponding authors are Prof. Yi Xie from the University of Science and Technology of China, Prof. Yongfu Sun from the University of Science and Technology of China, and Prof. Xingchen Jiao from Jiangnan University.

Link: https://doi.org/10.1039/D2CS00688J

Figure 1. Strategies, divided into two categories, for plastic conversion into valuable chemicals. The strategies executed under violent conditions involve pyrolysis, hydropyrolysis, solvolysis, and microwave catalysis, while the strategies carried out under mild conditions involve photocatalysis, electrocatalysis and biocatalysis.